Zhuzhou Jintai Cemented Carbide Co., Ltd is located in hometown of

Chinese carbide industry - Zhuzhou city, Hunan Province. The

company has more than 20 years’ experience in manufacture, design

and sale of various kinds of carbide products.

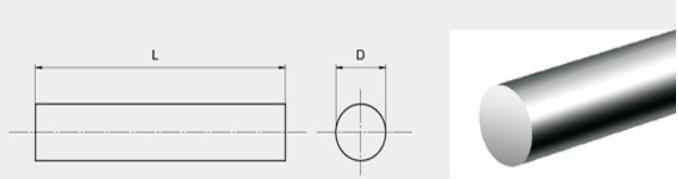

Our main products include: carbide end mills, carbide rods,

indexable inserts, brazed inserts, wire drawing dies, forging dies,

wood working tools, saw tips, mining buttons, etc

The company has passed ISO 9001: 2008 quality system,

possess advanced production equipment, complete testing

instrument, strong R&D center and QC team.

With excellent quality, strong technical support, and good

after-sales service, JINTAI Carbide brand products are sold to more

than 50 countries in the world, including Europe, USA, Southeast

Asia, Middle-East, South America, etc.

The company is dedicated to “Quality and Customer are first, “.

JINTAI Carbide is growing up with the World’s carbide technology,

to meet the demand of our customers from all over the world.